How small can we get with a functional gear part on a FDM printer? At this point, the internal gears for a differential are the limiting factor for designing a 3D printed RC car.

XMods Differential¶

Existing XMods use a compact design that works fairly well; however, it's hard to take apart without permanently damaging it so I've stuck to replicating other designs.

Right Angle Gears¶

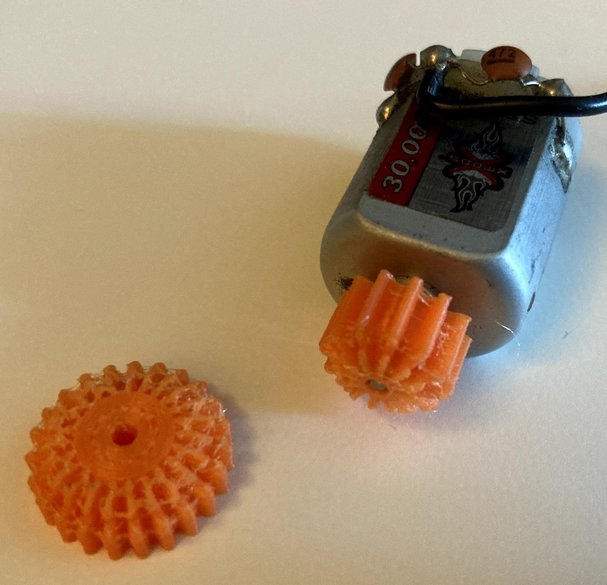

One of the key elements to replicating the XMods differential is a right angle drive from a longitudinal motor (or revisiting whether or not a longitudinal motor makes sense). So far, the right-angle gears haven't come out at a high quality, in part because they weren't designed with the extrusion width in mind. Another avenue of improvement is reducing the gear reduction required between the drive motor and the differential, which could reduce the number of teeth required, which would enable more sturdy, easier to print teeth.

Small Gears¶

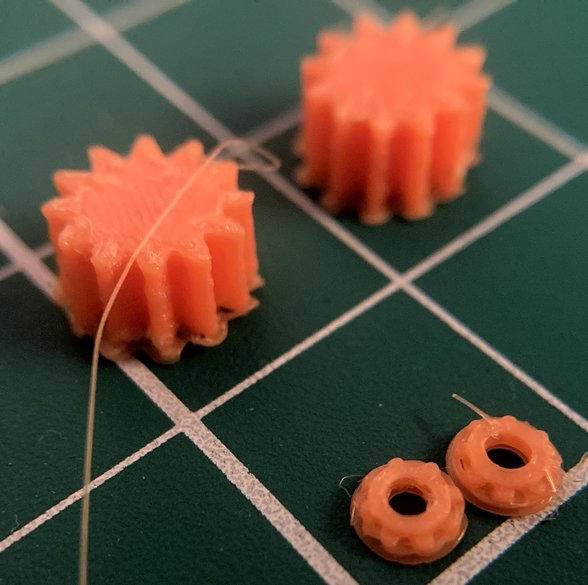

When taking into account the width of the extruder, it is easier to get small gears of various designs to print well. There are opportunities to go down a step in terms of extruder widths to print an even smaller gear; however, at this time, I've left some margin in an attempt to have a more reliable print and to maintain some strength. In the end, gears used in the differential are responsible for transmitting drive torque from the motor.

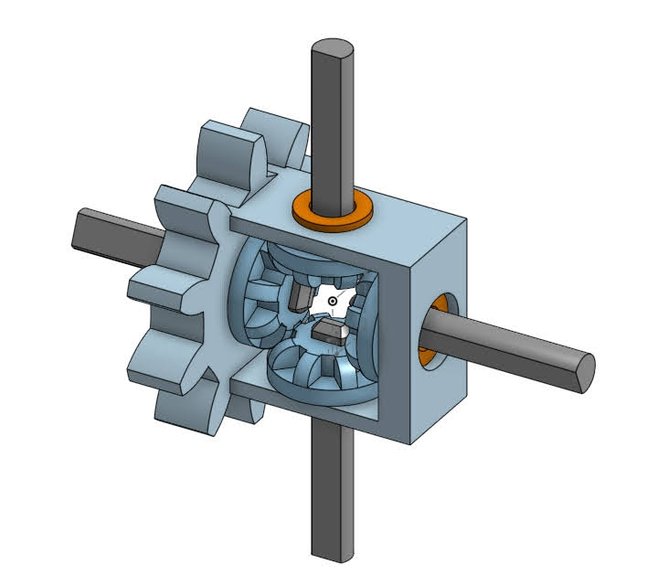

Proof of concept differential¶

These smallest (or nearly minimum size) gears, combined with a printed shaft and "bushings" (not shown) can enable a fairly compact differential design. The rendering shown isn't refined to reflect the final input gear (on the left); however, the internals are close to correct and reflect the layout that I'm using for testing.

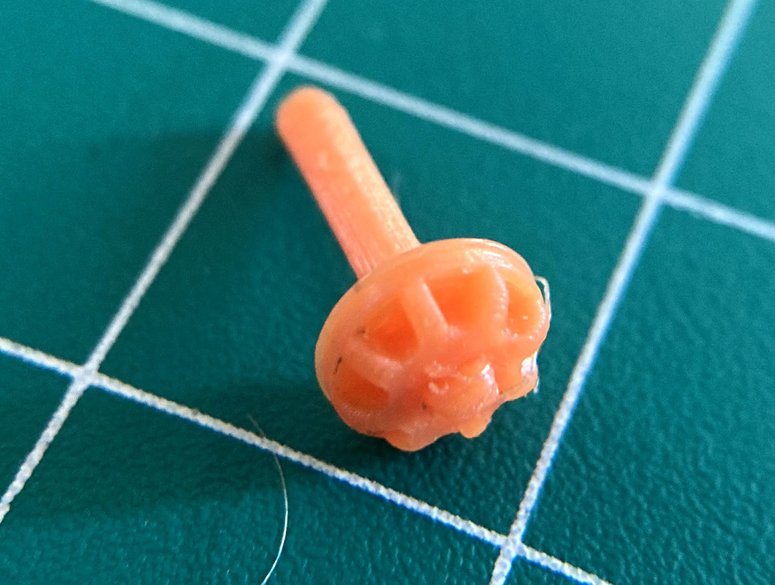

Taking a close look at the gear, it actually has come out pretty well. For reference, the squares are 10 mm to a side (and straight, the macro lens warps the image somewhat). At this scale, it was fairly tricky to actually get the shaft and the gear to press fit together. It took a couple prints to get the sizing right to get a nice fit without it seeming like it'd slip too much.