The Problem¶

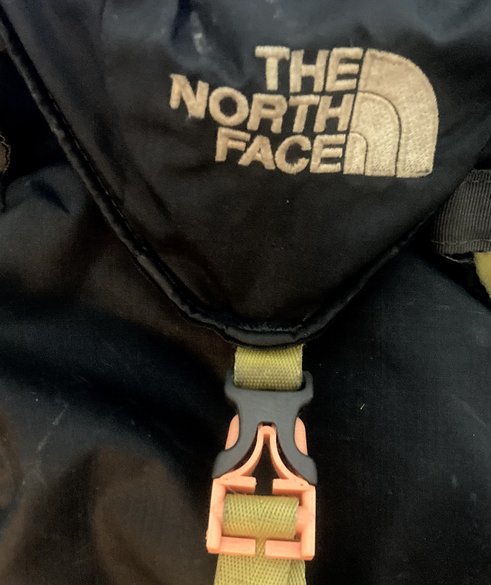

Let me introduce you to my backpack, which I have lovingly used for many years:

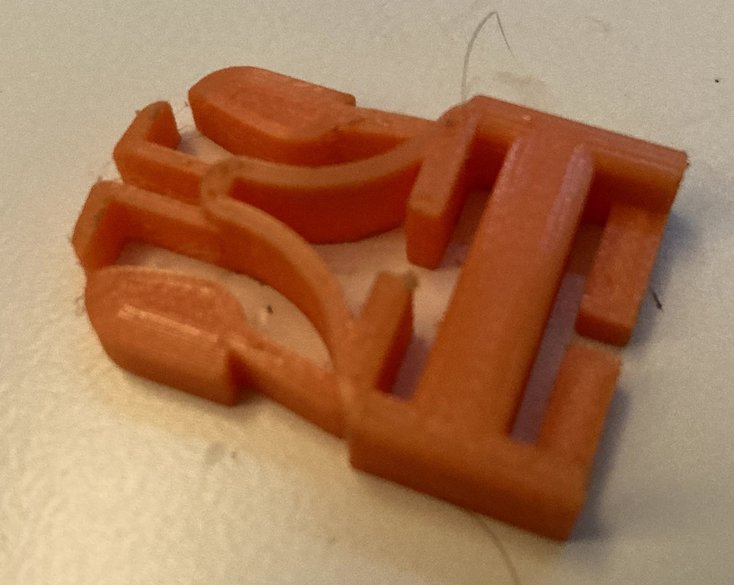

The left half of the insertion side of the clip broke off (I may or may not have stepped on it...)

The Solution¶

3D Printing to the rescue! I spent a lot of time with some calipers measuring different aspects of the clip. It turns out the key dimensions are the height of the inserted component and making sure it's not too long.

Getting to this point took 3 prints and lots of passes through the slicer. The fine geometry in general and some adhesion issues meant that the printing wasn't as reliable as simpler designs I've been printing recently.

Also, getting the fit right to be able to slip the existing webbing into the clip without it slipping out easily took a handful of tries to get right. Even after the first clip that snapped into place nicely enough, the grip on the webbing was fairly loose and would slide out. The bag would stay clipped, but not secured like with the non-printed design. The latest iteration largely addresses that, although I still see some room for improvement.

Overall, I'd say things come together pretty nicely.

Taking a closer look, there's also some room for improvement for some more cosmetic areas: The curvature at the interface between the existing grey side and the orange new print don't match that well. Also, in an attempt to make the design more robust to measurements, there is some slop, leading to a "panel gap"